Product information Product

Functional additives

Frotect

Frotect series are solvent borne water and oil repellent agents based on Perfluorinated Polyurethane used in Polyurethane artificial leather industry.

| Frotect | Solid(%) | Solvent | Viscosity(cps/25℃) | Characteristics | |

|---|---|---|---|---|---|

| Fluorine Based | F 2406 | 60±1 | DMF/MEK | Below 3,000cps | PFOA/PFOS free Good water repellent Good anti-hydrolysis |

| F 1304 | 60±1 | DMF/MEK | Below 1,500cps | PFOA/PFOS free Good compatibility with various PU resins and solvents Higher water repellent than F 2406 |

|

| F 4002 | 60±1 | DMF | Below 1,000cps | PFOA/PFOS free Higher performed grade Same Performance as C-8 fluorine compound |

|

| Silicone Based | NI-190 | 70±1 | DMF | Below 20,000cps | Fluorine free Good compatibility with various PU resins and solvents Good water repellent & anti-hydrolysis |

Easy-clean agent

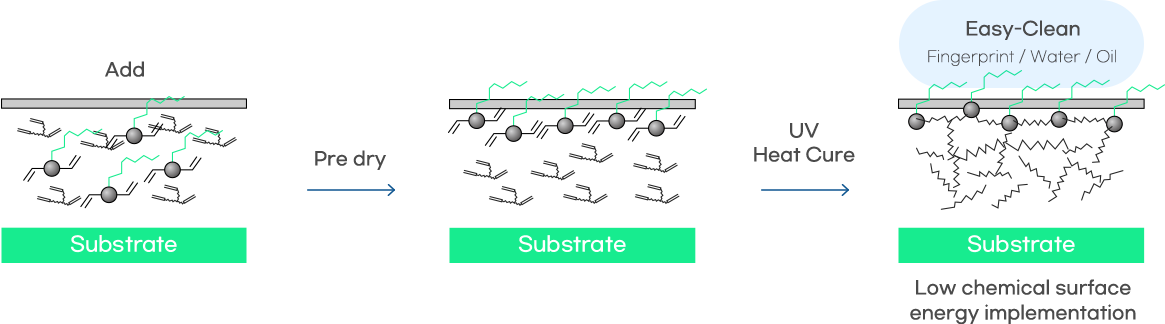

Easy-cleaning additives are easy to prevent the attachment of the pollutant by the surface treatment which mainly introduces molecular structure with low surface energy such as fluorine or silicone.

Principle of easy-cleaning additive

Easy-Clean coating : Chemical modification

Curable

| Properties | U-125 | H-1000 | |

|---|---|---|---|

| Type | - | Solvent-borne silicone modified urethane acrylate |

Solvent-borne silicone modified urethane |

| Appearance | Transparent liquid | Transparent | Transparent |

| Specification | Non-volatile content at 150℃/30min (%) | 40±1% | 25±1% |

| Function group | -Acrylate | -NCO | |

| Viscosity at 25℃, RVT, #3, 12rpm | Below 100 cps | Below 100cps | |

| Package | Drum | 15kg/160kg | 15kg/160kg |

Properties of easy-clean additive

- Surface additives that enhance surface cleaning by giving the paint a slip quality

- Improves graffiti prevention and tape releasing

- Applicable Solvent-borne system : UV-curable(U-125) / heat-curable(H-1000)

- Recommended amount : 0.1 to 5.0% for the entire mixture

Performance test results of UV curable easy-cleaning additives(U-125)

01 _ Contact angle data

| Contact Angle(Water) | Bare Film(188㎛) | U-125 |

|---|---|---|

| Degree(°) |  |

|

| 65.7° | 106.2° | |

| TEST | UV resin (solid 20%)

Usage of U-125 : 0.5% of total solution Coating thickness : 4㎛ Drying & UV-curing condition : 1min at Room temperature → 80℃*2min, UV cure 400mj/cm2 |

|

02 _ Wiping test

| Name pen Test | Bare Film(188㎛) | U-125 |

|---|---|---|

| Marking |  |

|

| Wipe |  |

|

| 0times | More than 20 times |

| Magic pen Test | Bare Film(188㎛) | U-125 |

|---|---|---|

| Marking |  |

|

| Wipe |  |

|

| 0times | More than 20 times |

Performance test results of heat curable easy-cleaning additives(H-1000)

| HDI trimer | H - 1000 | ||

|---|---|---|---|

| Properties | Poly-isocyanate (Normal) | Heat-curable (Functional : -NCO) | |

| Functional group(%) | NCO = 21.85% | NCO = 1.54% | |

| Solvent resistance | EtOH | 1500-1600 | 1400-1500 |

| MEK | 30-50 | 30-40 | |

| Gloss(60º) | 156 | 111.33 | |

| Water contact angle |  |

|

|

| Pencil hardness | B-HB | HB | |

| Usage | - | 3phr/total | |

| Hardness | - | Excellent functionality | |

| TEST | Resin : RA-2970 (Acryl polyol)

Crosslinker : C-HXR (HDI trimer) Film thickness : 40㎛(dry) Drying & curing condition : 80℃*30min |

||